KDC-ONE

- apteagency

- Sep 13, 2024

- 2 min read

Updated: Sep 29, 2024

Challenge: One of their leading production sites with $12 million a month revenue goals had a challenge of maintaining top line sales and profitability targets while being designated as a high mix low volume center for corporate production.

Highly manual processes, multiple daily production changeovers,and a fluctuating supply chain made streamlining inventory and automation production processes daunting if not seemingly difficult. Moreover, with over 80 production lines supporting the range of products, planning often was inefficient, direct labor was inefficient and capital maintenance and preventive maintenance programs were largely ineffective.

Solution: We architected and led a massive cross-departmental product rationalization program aimed at grouping over 1000-sku’s into “families” using filters such as:

Chemical properties of the materials being compounded

Special handling, aeration, heating or mixing requirements of the material

Dosing and filling requirements based on viscosity and throughput

Packaging and labeling requirements

Final cartoning, coding, serialization and palletizing needs

8 existing “generic” production lines were re-engineered to become capability-specific anchor lines, supporting the needs of these newly defined categorical production families and their forecasted volumes.

At this stage in the project, Eric transitioned from strategist to roll-up-the-sleeves program coordinator and implementation expert. Working across the operations, engineering, facilities teams and coordinating designs with automation providers, Eric led the design, validation and launch of each line over a 6 month period.

Highlighting his collaborative style, Eric also integrated the planning and operations teams leading to reorganization of their master planning platform to assign SKU’s to these specific lines, reducing the volatility in planning, and achieving repeatable throughput and reliable profitability for those products over the trailing 12 months.

Sustainment

As is the case in most transformation projects, the challenge is only 50% complete at implementation.. the other 50% is in keeping it going.

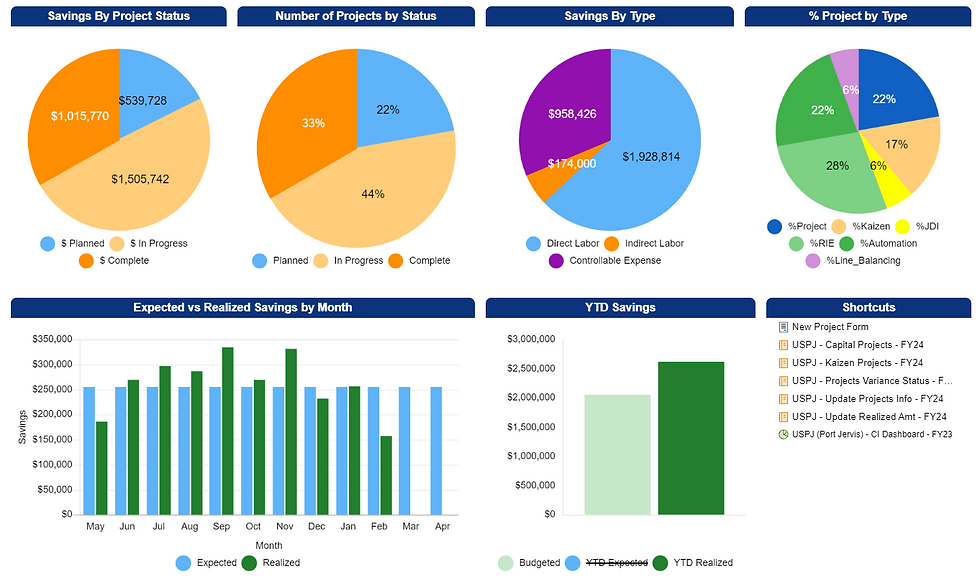

In order to maintain visibility of performance and efficiencies, we developed a visual dashboard incorporating all the important direct and indirect deficiency metrics that were important for a cross-functional team to maintain momentum and continued performance efficiency. This became a central point of review during weekly leadership meetings, and the barometer for real-time performance evaluation.

Results:

Throughput increased by 150% to 300% per production line.

Direct labor efficiencies improvements of 25%

OEE of production lines increased by 30%

Profitability (EBITA) increased from 6% to10% on high mix/low-volume portfolio

Gained market-share and mind-share from existing and new customers on strength and flexibility to deliver quality and affordable solutions across a range of low and high volumes.

Shifted a “culture of chaos” to a “culture of control”.

Implemented the same strategic planning process to 4 other key production sites across North America and Europe.

Comments